Our expertise for your projects

As a progressive and dynamic company, we strive to participate in current developments or even to act as a pacemaker for the respective market. Constant investments in our machinery as well as in our employees enable a high level of performance in order to always be able to meet all customer requirements.

rom our qualification as a manufacturer of various components, we derive our responsibility for the high-quality, flexible and timely repair of assemblies.

In order to fulfill these self-imposed requirements, we constantly ensure sufficient future-proof stocks in order to exclude waiting times due to missing spare parts. In addition, our employees are broadly trained, so that always motivated and well qualified specialists dedicate themselves to your individual order.

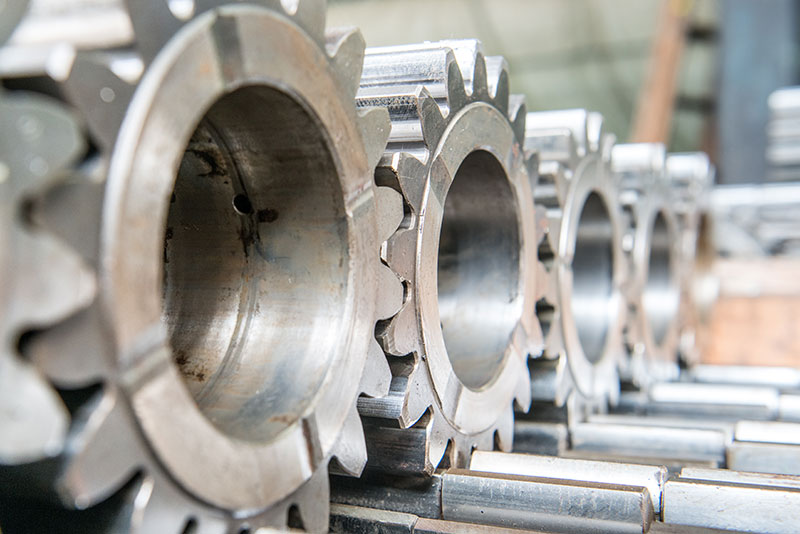

Our core capabilities in the areas of welding, gearbox and drive technology as well as machining enable us to offer repair services beyond our manufacturer portfolio:

e are one of the companies in Germany when it comes to complex tasks around welding technology. In order to meet current standards and customer requirements, we are constantly working on improvements to our welding processes and quality.

Jungenthal Wehrtechnik GmbH currently holds the following approvals:

The perfection of the machine equipment is complemented by the technical and craftsmanship skills of trained specialists. Only this combination enables the top performance for which JWT is known.